Experienced Engineering For All Plastic Extrusion Projects

Backed by the technical expertise of our in-house engineering and production staff, our 3D modeling systems allow us to efficiently develop the profile design and tooling required to produce products to our customers’ specific requirements. Backed by the technical expertise of our in-house engineering and production staff, our 3D modeling systems allow us to efficiently develop the profile design and tooling required to produce products to our customers’ specific requirements.

Consulting with the client to select the best materials for the intended application, we custom build the tooling and develop the production process that will meet the quality and production objectives with due consideration given to minimizing total cost.

Our experienced engineering and production staff, work hand-in-hand on all projects identifying potential issues and opportunities to optimize the design and production process for each project regardless of run size.

Our committed workforce ensures that our customers receive the right advice as their project moves from concept to reality. |

Custom Extrusion Profile

TPO & Santoprene™- Emergency Relief Shelter Component

Tubular Extrusion Profile

ABS- Large ABS Tube

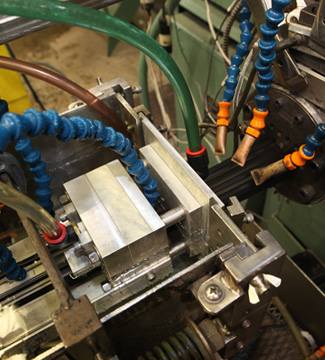

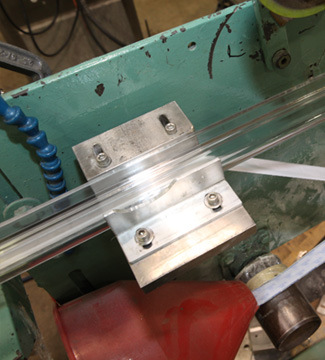

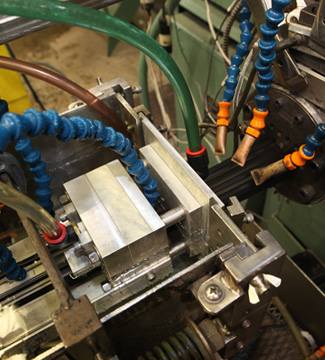

Extrusion Production Floor

Oversize Extrusion Profile

PVC - Floor wire cover

Co-Extrusion Extrusion Profile

PVC & Flexible PVC - Co-extruded Reversable Wire conduit

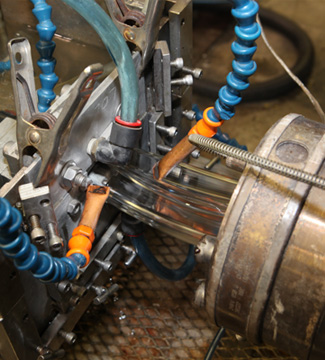

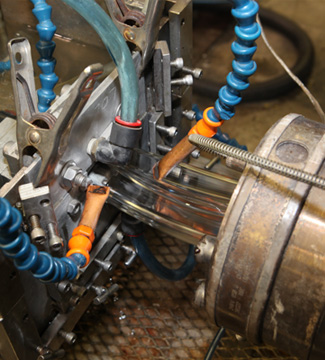

Multi-port extrusion leaving die

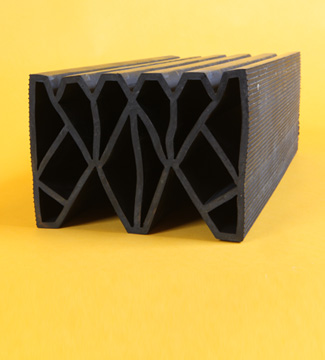

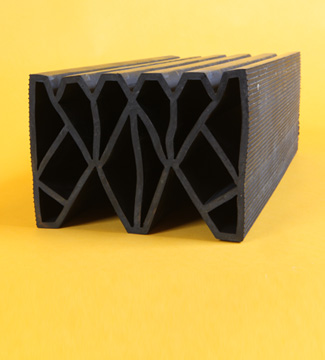

Multiport Hole Extrusion Profile

Santoprene™ - Expansion Joint for construction

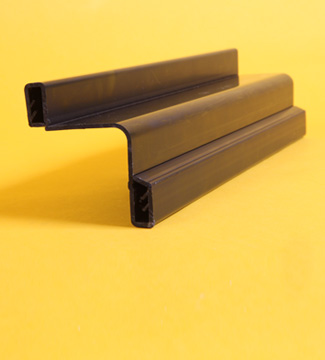

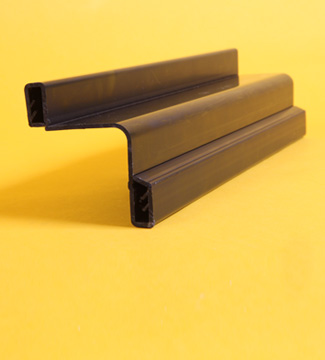

Door And Window Profile

PVC - Window and Door Extrusion

Co-extrusion leaving die

Point Of Purchace Profile

PVC - Ice Cream Cooler Glass Frame

Automotive Profile

Santoprene™ - Running Board Cover

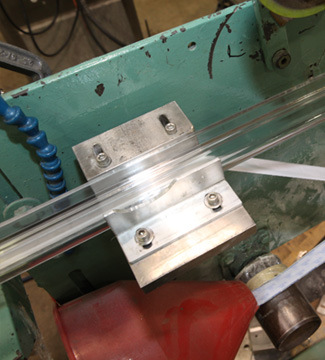

In-line processing – applying adhesive tape

Pool Rail Profile

PVC - Pool Coping

|

Backed by the technical expertise of our in-house engineering and production staff, our 3D modeling systems allow us to efficiently develop the profile design and tooling required to produce products to our customers’ specific requirements.

Backed by the technical expertise of our in-house engineering and production staff, our 3D modeling systems allow us to efficiently develop the profile design and tooling required to produce products to our customers’ specific requirements.