| United Plastics Components Launches Video Click here for full article |

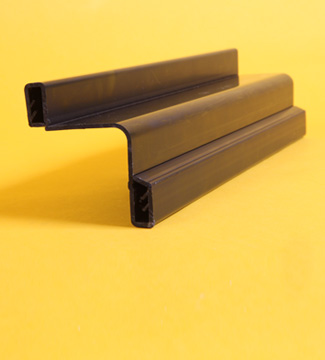

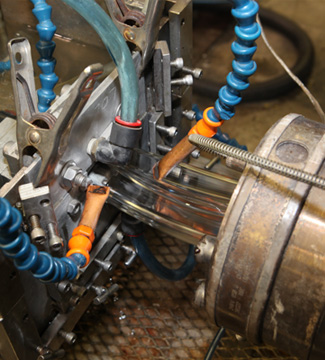

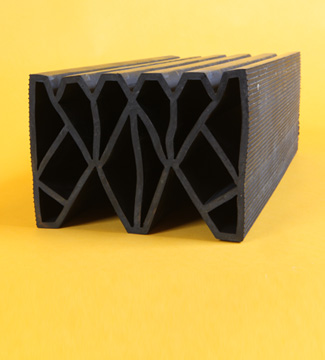

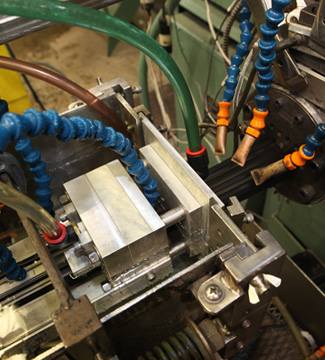

Complex Plastic Extrusion Shapes And SizesUnited Plastic Components Inc. (UPC) provides high quality profile extrusions to customer specifications from its modern 32,000 square foot facility in Exeter, Ontario. Capable of working with a wide range of materials, we specialize in the design and development of tooling and equipment to produce complex shapes and profiles ranging from simple tubes and channels, to complex porthole profiles, slatwall extrusions and multiple co-extruded and tri-extruded profiles. Click here to see samples of plastic extrusion projects completed at UPCAs a custom extruder, we provide custom solutions in collaboration with program managers, purchasing agents, design engineers and innovative entrepreneurs looking for a supplier to produce, source and offer expertise for extruded products. Look to our in-house Engineering Department to design and develop the tooling, equipment and processes and to help select the right material for your specific requirements. We offer a wide range of post extrusion processes to complete your project whether it is for sale or the next manufacturing step with the focus on timely delivery of your finished product. With a long history of serving customers worldwide, UPC understands the value of providing flexible order-response timing, on-time delivery, and one-on-one service. Walkthrough the UPC step-by-step extrusion process to see how we can help you to design, specify and manage your product development process from beginning to end. |

|