Quality, Consistency, Repeatability: Our Measure Of Success

United Plastic Components Inc. holds the following certificates:

United Plastic Components Inc. displays this certification by our main entrance as a visible reminder of our commitment to our customers and to continually improve the quality or the service we provide. United Plastic Components Inc. displays this certification by our main entrance as a visible reminder of our commitment to our customers and to continually improve the quality or the service we provide.

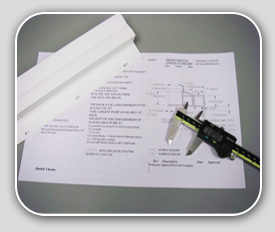

Once an extrusion profile is processed, we ensure its conformance to the established quality requirements of the project. Records are filed of all critical dimensional, visual checks and batch numbers and reference samples are retained from every run. These checks are repeated, as required in the established quality plan, to ensure consistent and repeatable product characteristics.

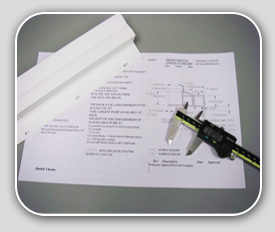

Our On-site Quality Lab

The UPC Quality Lab, located just a step away from our extrusion lines, is managed by dedicated Quality Managers. The Quality Team also provides hands-on support through the entire production process - from concept design to final shipping. The lab is fully equipped to perform testing and documentation of: The UPC Quality Lab, located just a step away from our extrusion lines, is managed by dedicated Quality Managers. The Quality Team also provides hands-on support through the entire production process - from concept design to final shipping. The lab is fully equipped to perform testing and documentation of:

- Finished Product Integrity & Uniformity

- Specification Conformance, Measure and Fit

- Colour Match

- Impact Characteristics

Our success is measured by the growth, prosperity and satisfaction attained by our customers, our employees, our suppliers and our shareholders. |

Custom Extrusion Profile

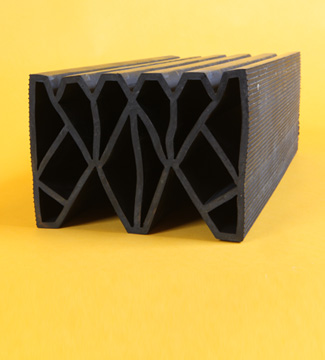

TPO & Santoprene™- Emergency Relief Shelter Component

Tubular Extrusion Profile

ABS- Large ABS Tube

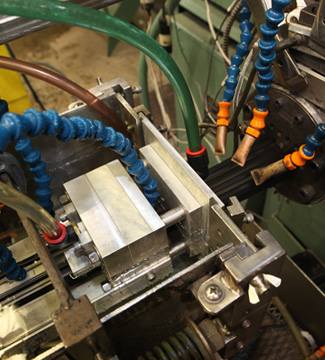

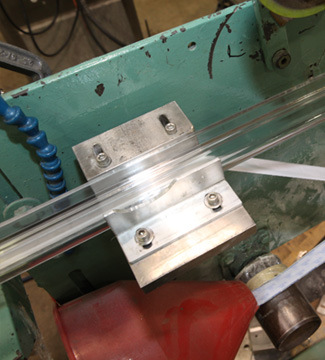

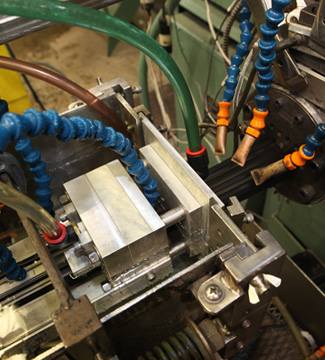

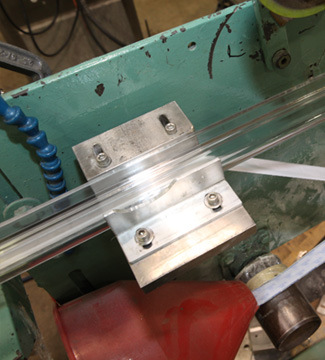

Extrusion Production Floor

Oversize Extrusion Profile

PVC - Floor wire cover

Co-Extrusion Extrusion Profile

PVC & Flexible PVC - Co-extruded Reversable Wire conduit

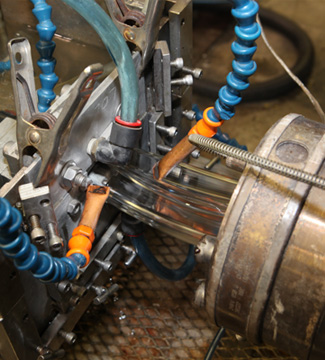

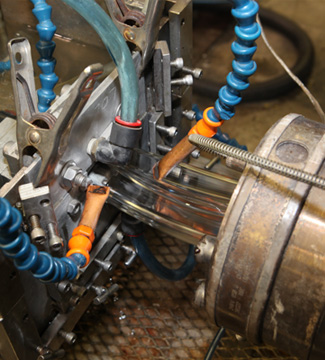

Multi-port extrusion leaving die

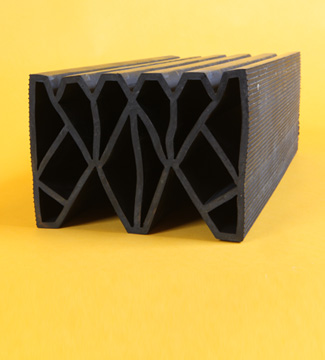

Multiport Hole Extrusion Profile

Santoprene™ - Expansion Joint for construction

Door And Window Profile

PVC - Window and Door Extrusion

Co-extrusion leaving die

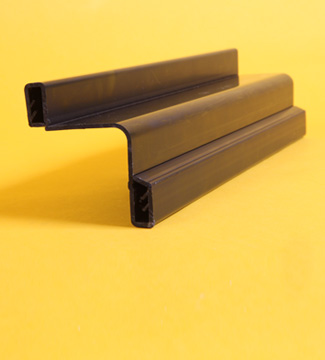

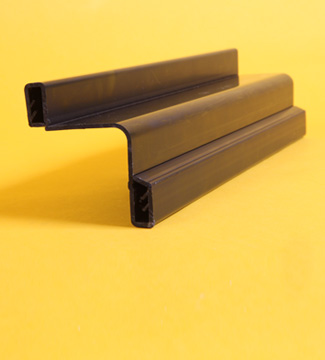

Point Of Purchace Profile

PVC - Ice Cream Cooler Glass Frame

Automotive Profile

Santoprene™ - Running Board Cover

In-line processing – applying adhesive tape

Pool Rail Profile

PVC - Pool Coping

|

United Plastic Components Inc. displays this certification by our main entrance as a visible reminder of our commitment to our customers and to continually improve the quality or the service we provide.

United Plastic Components Inc. displays this certification by our main entrance as a visible reminder of our commitment to our customers and to continually improve the quality or the service we provide. The UPC Quality Lab, located just a step away from our extrusion lines, is managed by dedicated Quality Managers. The Quality Team also provides hands-on support through the entire production process - from concept design to final shipping. The lab is fully equipped to perform testing and documentation of:

The UPC Quality Lab, located just a step away from our extrusion lines, is managed by dedicated Quality Managers. The Quality Team also provides hands-on support through the entire production process - from concept design to final shipping. The lab is fully equipped to perform testing and documentation of: