ABS (Acrylonitrile-Butadine-Styrene)

This material is a terpolymer of acrylonitrile, butadine and styrene. Usual compositions are about half styrene with the balance divided between butadiene and acrylonitrile. Considerable variation is possible. Many blends with other materials such as poly vinyl chloride, polycarbonates and polysulfones have been developed and are the most common class of plastics used in electroplated metal coatings for decorative hardware.

ADVANTAGES:

- Good impact resistance with toughness and rigidity

- Metal coatings have excellent adhesion to ABS

- Formed by conventional thermoplastic methods

- A light-weight plastic

DISADVANTAGES AND LIMITATIONS:

- Poor solvent resistance

- Low dielectric strength

- Only low elongations available

- Low continuous service temperature

TYPICAL APPLICATIONS:

Automotive hardware, appliance cases, pipe, plated items.

Visit the IDES database for detailed specifications. |

Custom Extrusion Profile

TPO & Santoprene™- Emergency Relief Shelter Component

Tubular Extrusion Profile

ABS- Large ABS Tube

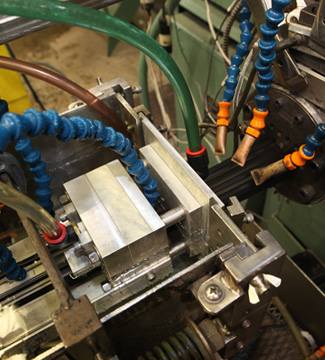

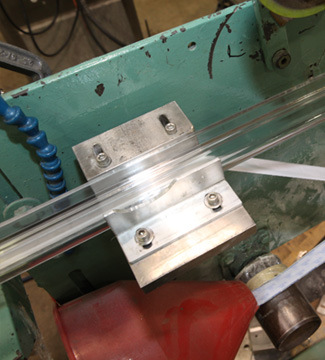

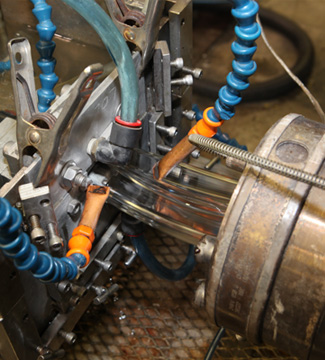

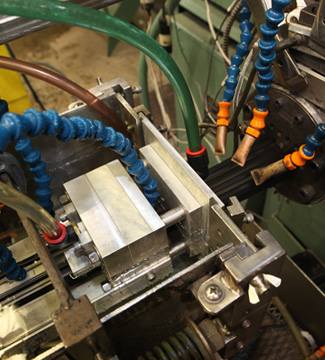

Extrusion Production Floor

Oversize Extrusion Profile

PVC - Floor wire cover

Co-Extrusion Extrusion Profile

PVC & Flexible PVC - Co-extruded Reversable Wire conduit

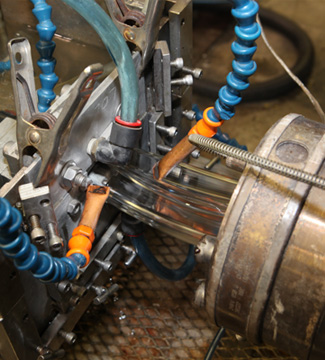

Multi-port extrusion leaving die

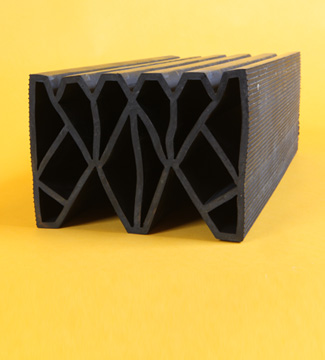

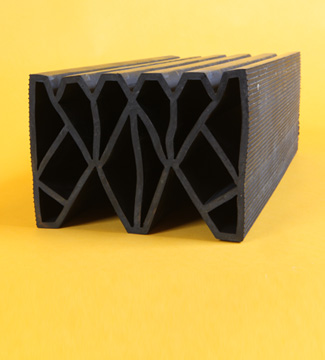

Multiport Hole Extrusion Profile

Santoprene™ - Expansion Joint for construction

Door And Window Profile

PVC - Window and Door Extrusion

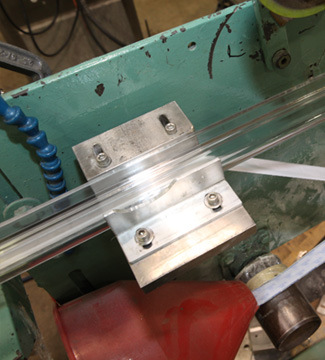

Co-extrusion leaving die

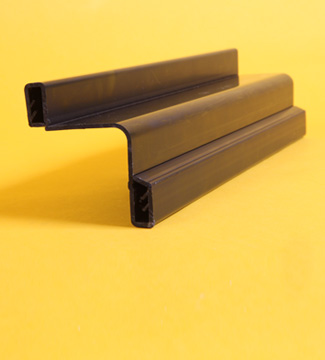

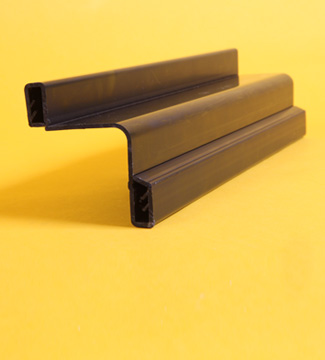

Point Of Purchace Profile

PVC - Ice Cream Cooler Glass Frame

Automotive Profile

Santoprene™ - Running Board Cover

In-line processing – applying adhesive tape

Pool Rail Profile

PVC - Pool Coping

|