| United Plastics Components Launches Video Click here for full article |

Flexible PVC (Polyvinyl Chloride)Unmodified polyvinylchloride is a very rigid thermoplastic. Flexibility can be increased over a wide range by adding varying amounts of several plasticizers such as dioctyl phthalate. A frequent method of processing PVC involves the suspension of solid particles of the polymer in an appropriate plasticizer. This suspension, a "plastisol," is then heated resulting in a homogenous system which becomes a flexible solid upon cooling. Usage of PVC has grown steadily since its introduction in the early 1930s to become a very widely used plastic in a myriad of uses from films and mouldings to extruded pipe. PVC has excellent resistance to water and aqueous solutions, but it is attacked severely by stronger solvents such as aromatic hydrocarbons, ketones, esters and chlorinated solvents. Recently discovered health hazards due to extended exposure to the vinyl chloride monomer have resulted in strict production controls. Several alloys and copolymers are possible with PVC, including styrene and acrylonitrile. See also polyvinyl chloride/vinylidene chloride. ADVANTAGES:

DISADVANTAGES AND LIMITATIONS:

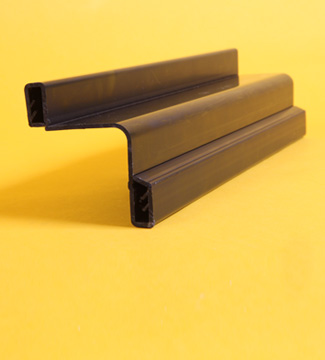

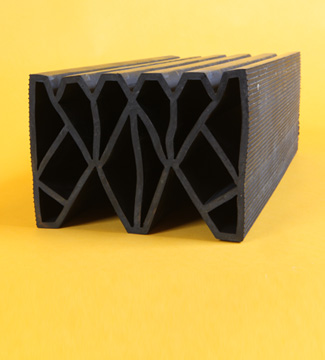

TYPICAL APPLICATIONS:Pipe, extruded wire covering, toys, bottles, door and window components, film and fabric coatings. Visit the IDES database for detailed specifications. |

|