PC (Polycarbonate)

Although some structural variations are possible, the most common system is formed by reaction of bispenol A and phosgene. Its applications are almost always those which take advantage of its unique high impact strength. Recently, additional interest has resulted because of its low flammability. Some studies are currently underway to further improve this characteristic.

ADVANTAGES:

- High impact strength

- Low flammability

- Thermoplastic processing methods

DISADVANTAGES AND LIMITATIONS:

- Subject to stress cracking

- Fairly high processing temperatures required (550 F)

- Degrades upon extended residence time in processing equipment

- Solvent resistance is only fair

TYPICAL APPLICATIONS:

Windows, helmets, instrument cases and mechanical goods

Visit the IDES database for detailed specifications. |

Custom Extrusion Profile

TPO & Santoprene™- Emergency Relief Shelter Component

Tubular Extrusion Profile

ABS- Large ABS Tube

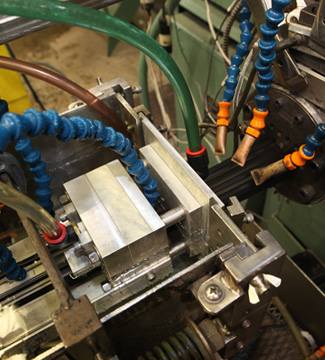

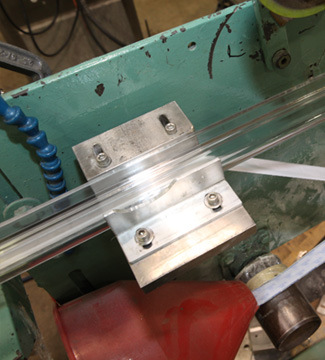

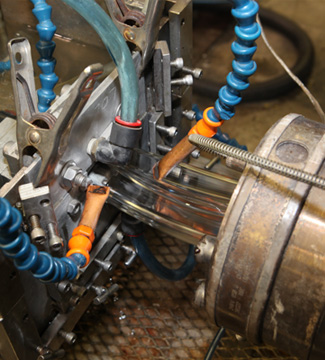

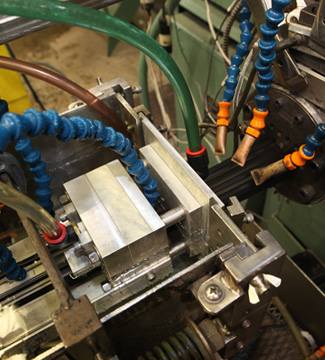

Extrusion Production Floor

Oversize Extrusion Profile

PVC - Floor wire cover

Co-Extrusion Extrusion Profile

PVC & Flexible PVC - Co-extruded Reversable Wire conduit

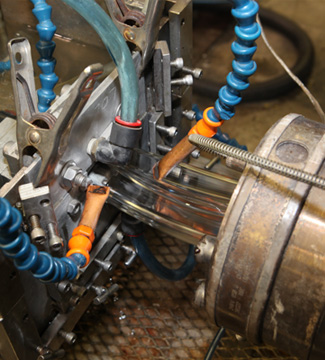

Multi-port extrusion leaving die

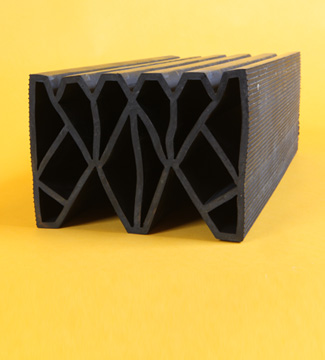

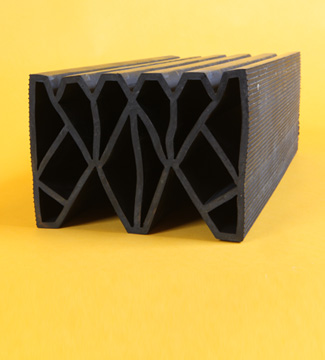

Multiport Hole Extrusion Profile

Santoprene™ - Expansion Joint for construction

Door And Window Profile

PVC - Window and Door Extrusion

Co-extrusion leaving die

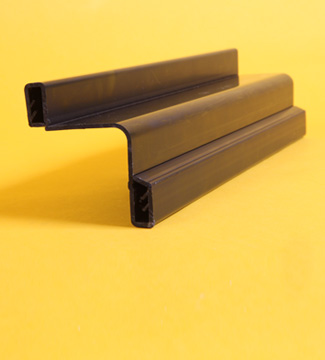

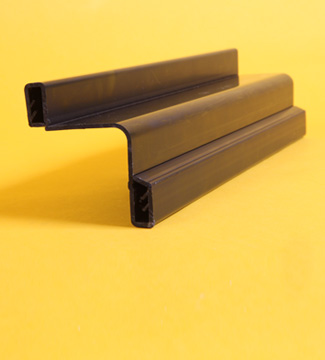

Point Of Purchace Profile

PVC - Ice Cream Cooler Glass Frame

Automotive Profile

Santoprene™ - Running Board Cover

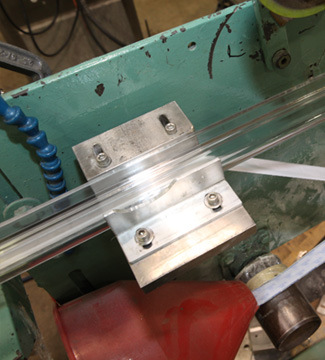

In-line processing – applying adhesive tape

Pool Rail Profile

PVC - Pool Coping

|