POLYPROPYLENE (PP)

This polyolefin is readily formed by polymerizing propylene with suitable catalysts, generally aluminum alkyl and titanium tetrachloride. Polypropylene properties vary according to molecular weight, method of production, and the copolymers involved. Generally polypropylene has demonstrated certain advantages in improved strength, stiffness and higher temperature capability over polyethylene. Polypropylene has been very successfully applied to the forming of fibers due to its good specific strength which is why it is the single largest use of polypropylene. Polypropylene also happens to be one of the lightest plastics available with a density of 0.905 g/cm².

ADVANTAGES:

- Homopolymer

- Processability, Good

- Food Contact Acceptable

- Stiffness, Good

- Impact Resistance, Good

- Copolymer

- Flow, High

- Impact Resistance, High

- Chemically Coupled

DISADVANTAGES AND LIMITATIONS:

- Degraded by UV

- Flammable, but retarded grades available

- Attacked by chlorinated solvents and aromatics

- Difficult to bond

- Several metals accelerate oxidative degrading

- Low temperature impact strength is poor

TYPICAL APPLICATIONS:

- Automotive Applications

- Household Goods

- Film

- Containers

- Appliances

- Packaging

- Electrical/Electronic Applications

- Industrial Applications

- General Purpose

Visit the IDES database for detailed specifications. |

Custom Extrusion Profile

TPO & Santoprene™- Emergency Relief Shelter Component

Tubular Extrusion Profile

ABS- Large ABS Tube

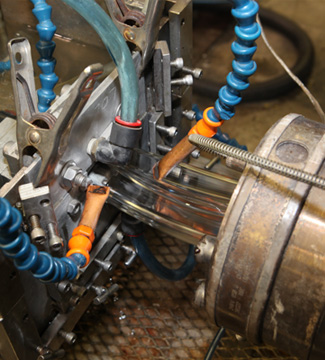

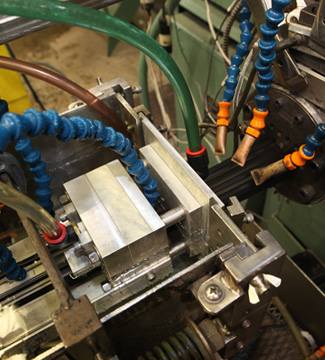

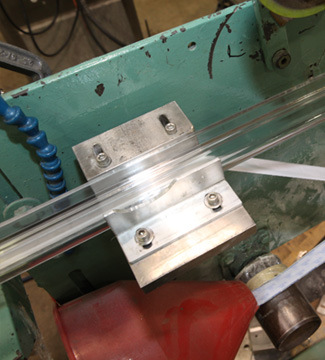

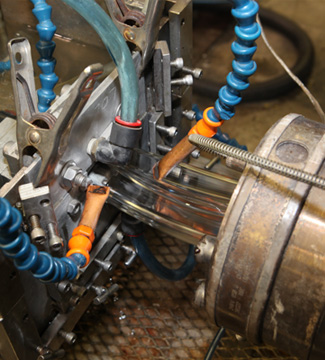

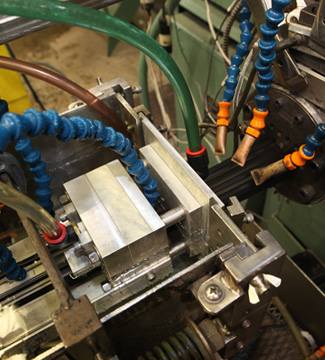

Extrusion Production Floor

Oversize Extrusion Profile

PVC - Floor wire cover

Co-Extrusion Extrusion Profile

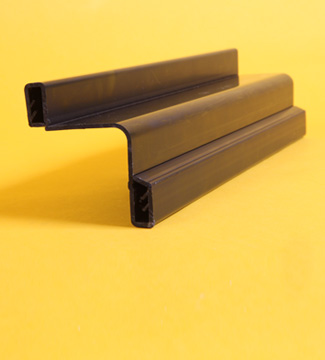

PVC & Flexible PVC - Co-extruded Reversable Wire conduit

Multi-port extrusion leaving die

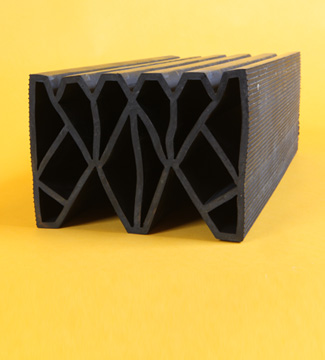

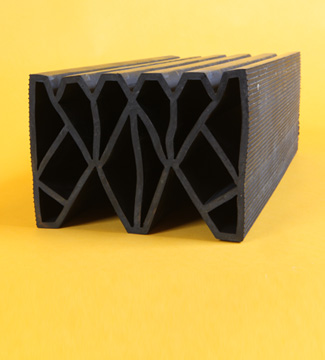

Multiport Hole Extrusion Profile

Santoprene™ - Expansion Joint for construction

Door And Window Profile

PVC - Window and Door Extrusion

Co-extrusion leaving die

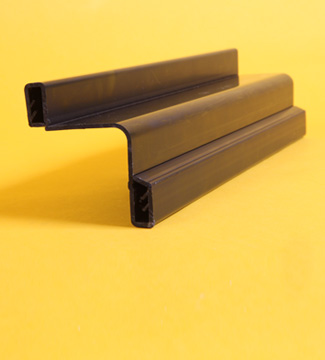

Point Of Purchace Profile

PVC - Ice Cream Cooler Glass Frame

Automotive Profile

Santoprene™ - Running Board Cover

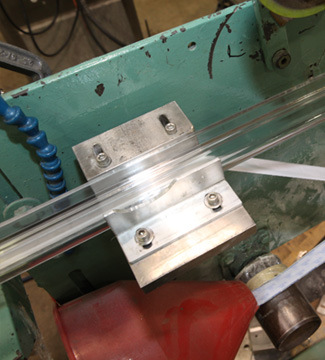

In-line processing – applying adhesive tape

Pool Rail Profile

PVC - Pool Coping

|